At Luminar Sdn. Bhd., We understand that every business has unique needs. That’s why we design and deliver fully customized laser solutions—built to match your processes, materials, and production goals. From concept to integration, we provide systems that fit seamlessly into your workflow.

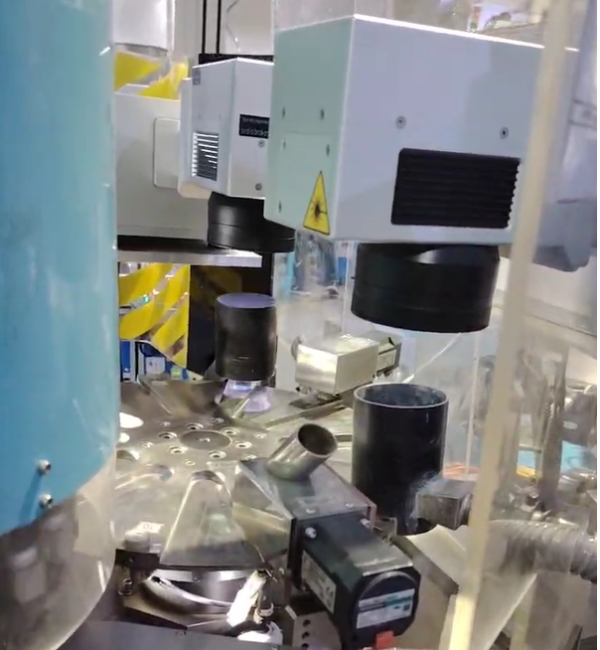

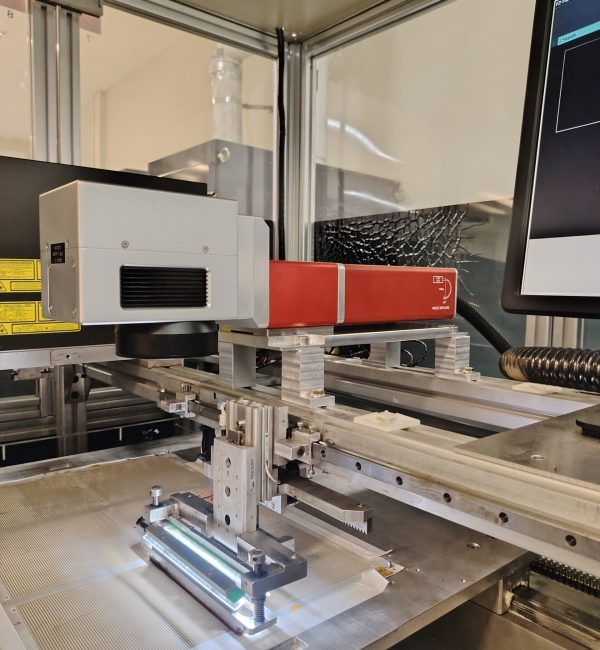

Customized solutions go beyond standard laser systems by adapting hardware, software, and workflows to meet specific requirements. Whether it’s integrating laser technology into existing production lines, automating processes, or developing specialized fixtures, customization ensures that you get maximum performance designed to your business.

Unlike off-the-shelf systems, customized solutions offer flexibility, efficiency, and scalability—ensuring that your investment aligns perfectly with your operational goals.

Why Choose Customized Laser Solutions?

Every solution is engineered based on your materials, processes, and specifications.

Compatible with your existing machines, software, and workflows.

Supports robotics, conveyors, and automated handling to streamline operations.

From initial consultation to after-sales care, our experts work alongside your team.

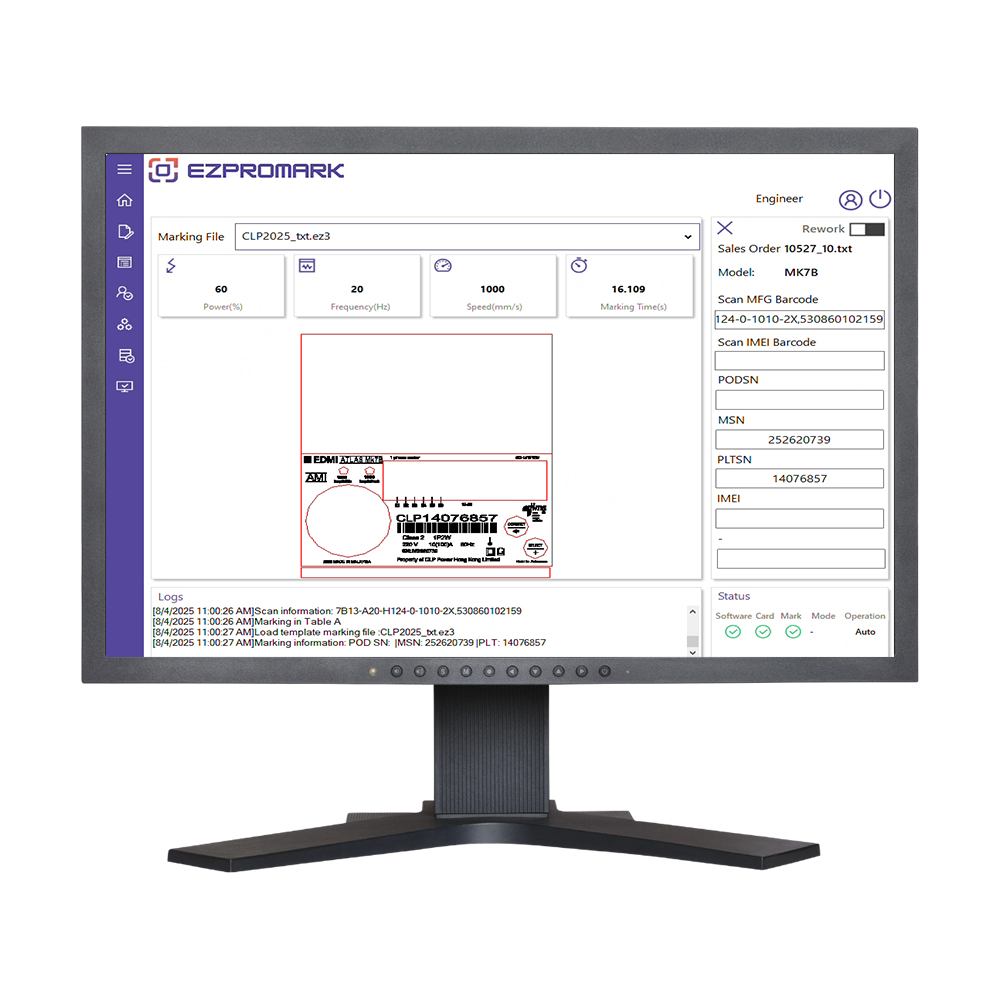

Our Custom Laser Control & Automation Software is designed to streamline and optimize laser application. Custom to meet your unique production requirements, the software integrates seamlessly with your systems, enabling precise parameter control, automated workflows, and real-time monitoring. With support for custom layouts, variable data input, and process validation, it ensures efficiency, consistency, and high-quality results across every application.

Dynamically handles barcodes, QR codes, text, and part numbers from databases or external systems.

Provides precise control of laser parameters (power, frequency, pulse width, speed) and direct I/O interfacing for automation with sensors, actuators, and safety interlocks.

Connects with SQL/SQLite/MySQL databases to retrieve variable data (serial numbers, barcodes, orders) and store production logs.

Supports TCP/IP and RS-232 for flexible connectivity with PLCs, devices, and factory networks.

Enables seamless integration with semiconductor and electronics manufacturing systems.

Luminar

Typically replies within minutes

Welcome to Luminar, your trusted partner in laser technology. How may we assist you?

WhatsApp Us

Online | Privacy policy

WhatsApp us