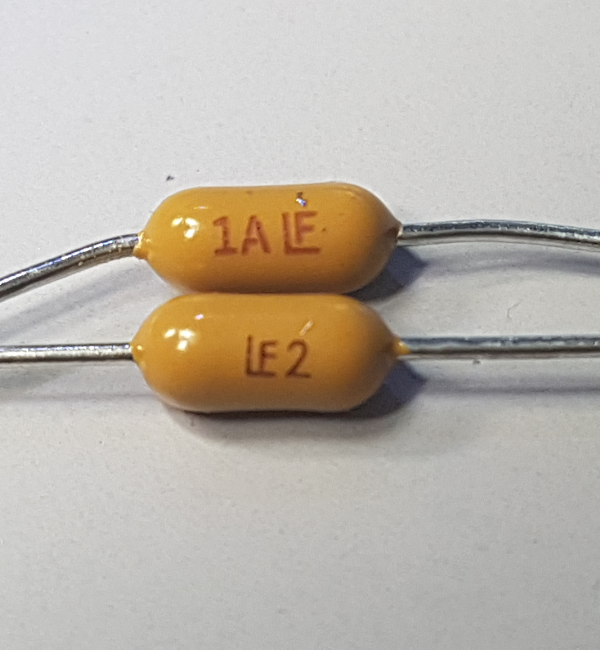

Laser technology enables precise spot and seam welding for connectors, sensor housings, and micro-contacts. It is especially effective for assembling battery packs and small electronic modules. Additionally, it provides durable wire and cable marking for harnesses and connectors. This ensures both reliable performance and long-term traceability in electrical applications.