Luminar Sdn. Bhd. started developing laser cleaning solution 20 years ago for the semiconductor industry. The cooperation with CleanLaser GmbH offers a modern, safe, and efficient way to clean semicon mold surfaces without the risks of damaging the mold. Unlike traditional methods, our laser cleaning technology removes rust, paint, and contaminants with precision and care.

Laser cleaning is a cutting-edge process that uses a powerful laser beam to remove impurities, coatings, or oxidation from a surface. This technology is non-contact and non-abrasive, which means it cleans without physically touching or damaging the material underneath. It is a preferred solution for industries that require delicate yet effective cleaning methods.

Unlike conventional methods like sandblasting, chemical treatments, or abrasive cleaning, laser cleaning is cleaner, safer, and more efficient. It does not produce hazardous waste, requires no harsh chemicals, and delivers consistent results every time.

Why Choose Laser Cleaning Over Traditional Methods?

Removes contaminants without harming the base material, perfect for components that demand high accuracy.

Removes contaminants without harming the base material, perfect for components that demand high accuracy.

Eliminates the need for consumables like sand, solvents, or blasting materials.

Works on metals, alloys, plastics, and even delicate historical surfaces.

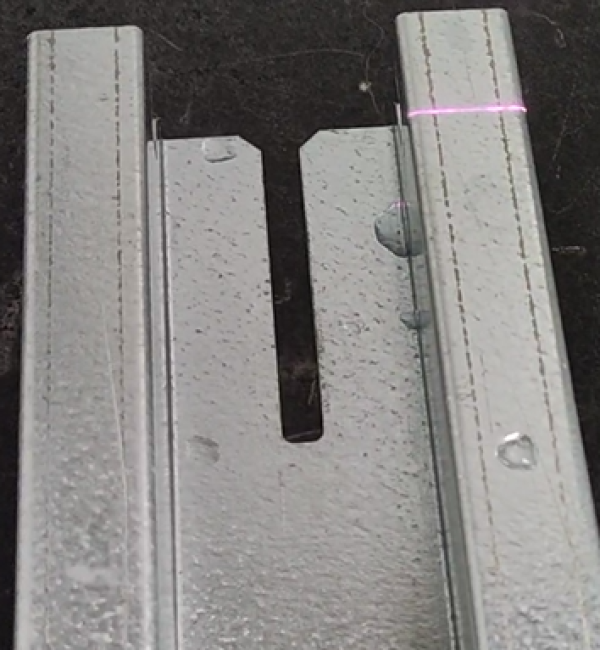

Laser cleaning in electronics and semiconductor applications removes thin oxide films from contacts, connectors, and micro-circuits to restore conductivity, clears soldering flux and contaminants from PCBs without damaging components, safely cleans wafers, microchips, and other sensitive parts without mechanical or chemical risk, and eliminates oxides or residues from lead frames prior to semiconductor packaging.

Laser cleaning in automotive applications removes rust, oxides, and scale from engine components, gears, and chassis parts before painting or coating, cleans weld seams before and after welding to ensure strong joints, strips old paint or coatings from car body panels without damaging the base metal, and prepares surfaces for adhesive bonding or coating to achieve superior adhesion quality.

In Industrial applications, laser cleaning is widely used for removing rust, oxides and other surface contaminants from machinery and production equipment. It is highly effective for cleaning molds without abrasion, restoring them for repeated use.

Luminar

Typically replies within minutes

Welcome to Luminar, your trusted partner in laser technology. How may we assist you?

WhatsApp Us

Online | Privacy policy

WhatsApp us