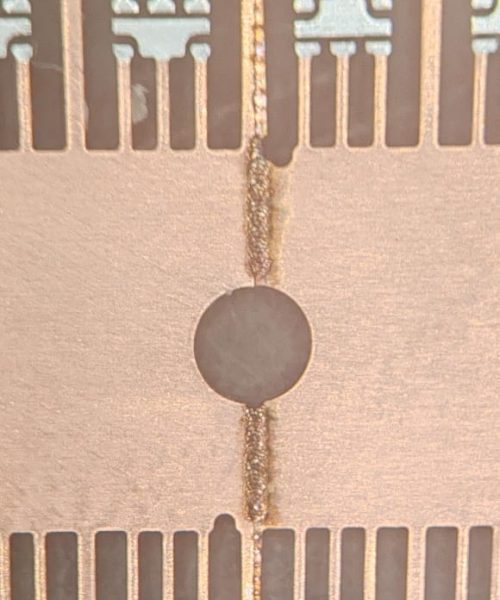

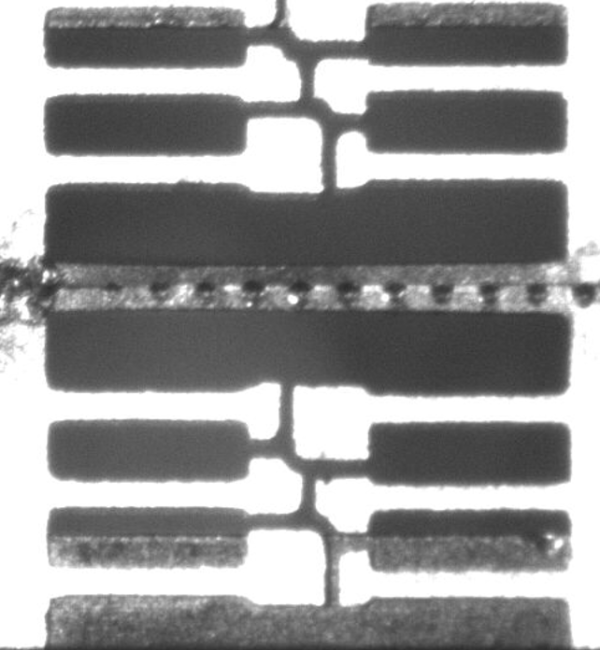

In the electronics industry, laser welding is used for battery pack assembly, including electric vehicle (EV) batteries, ensuring strong and reliable connections. It is also applied to sensor housings and connectors for precise, sealed joints, as well as to microelectronic components and circuit boards where accuracy and minimal thermal impact are critical.