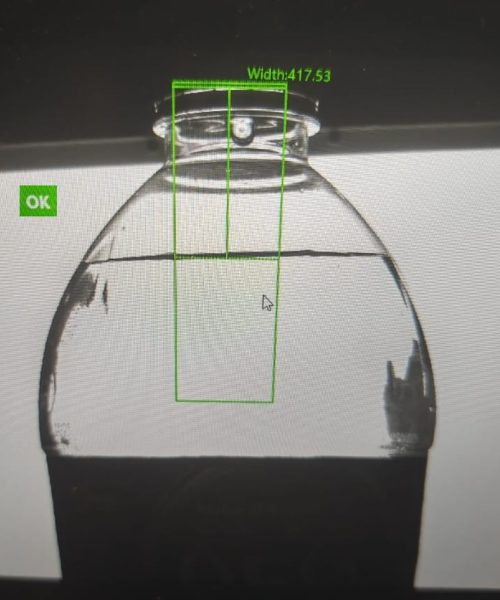

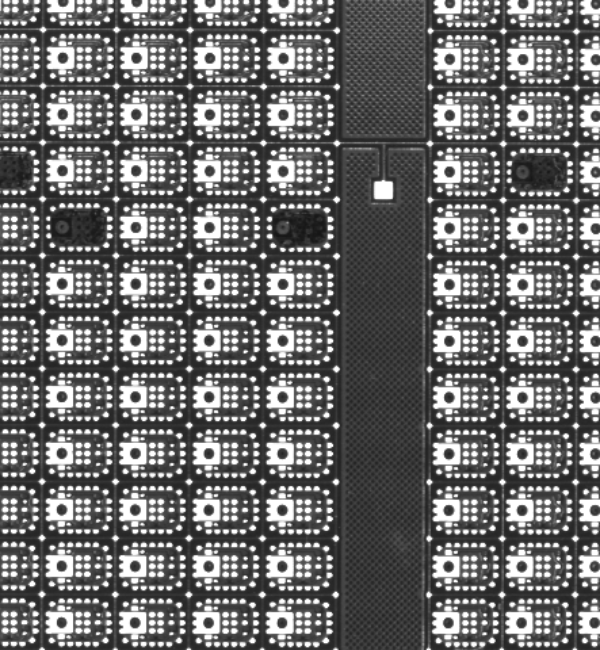

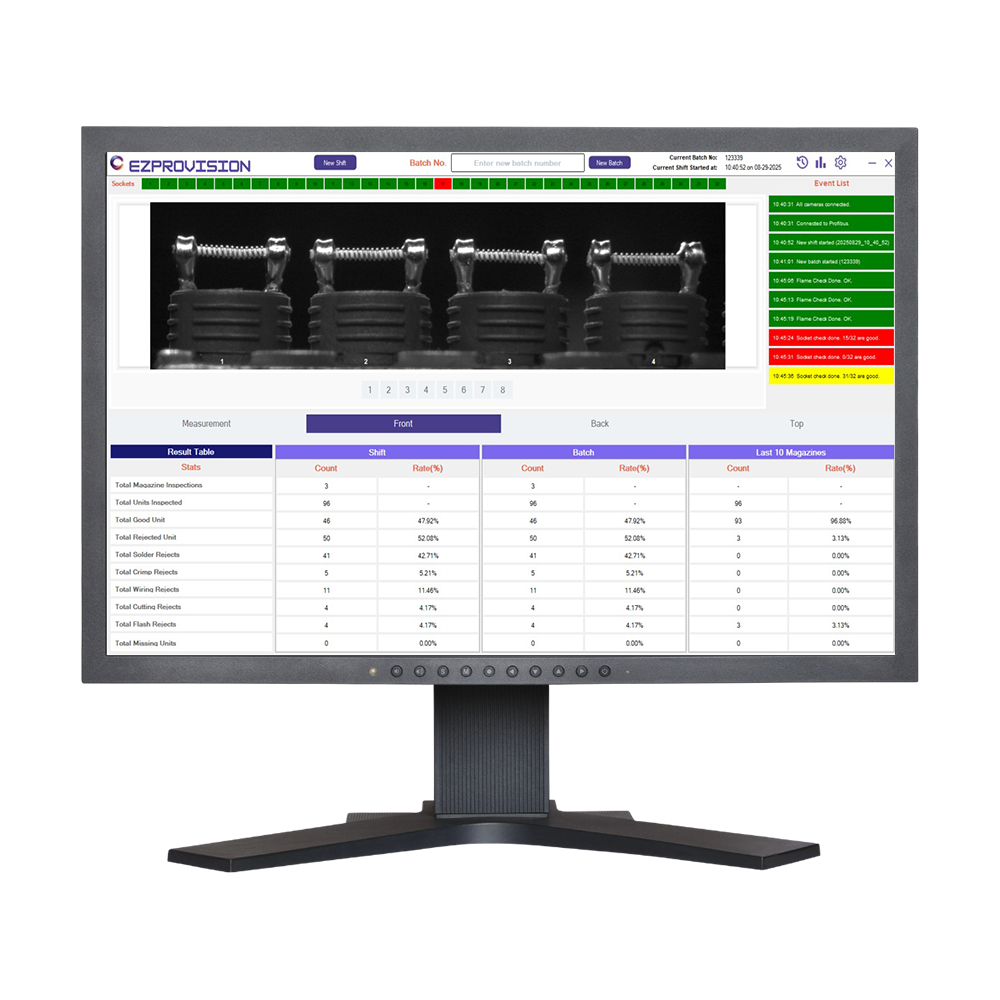

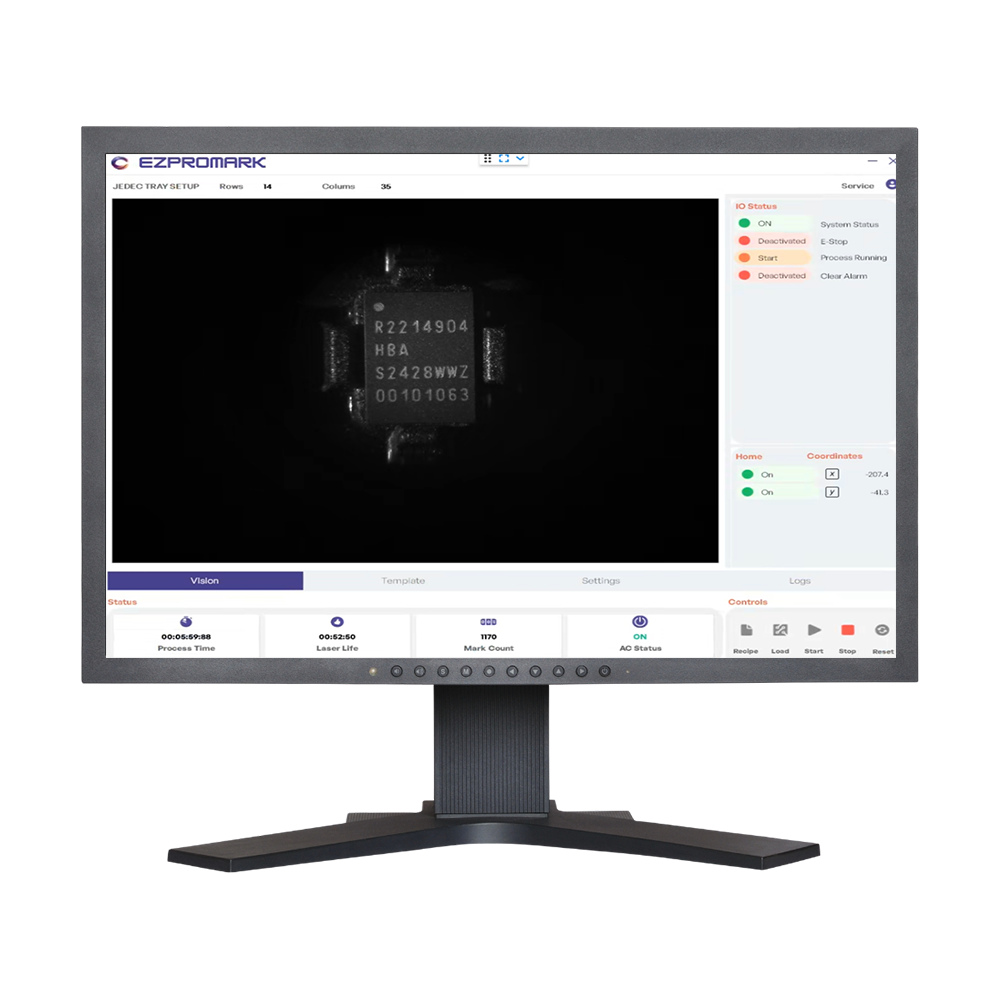

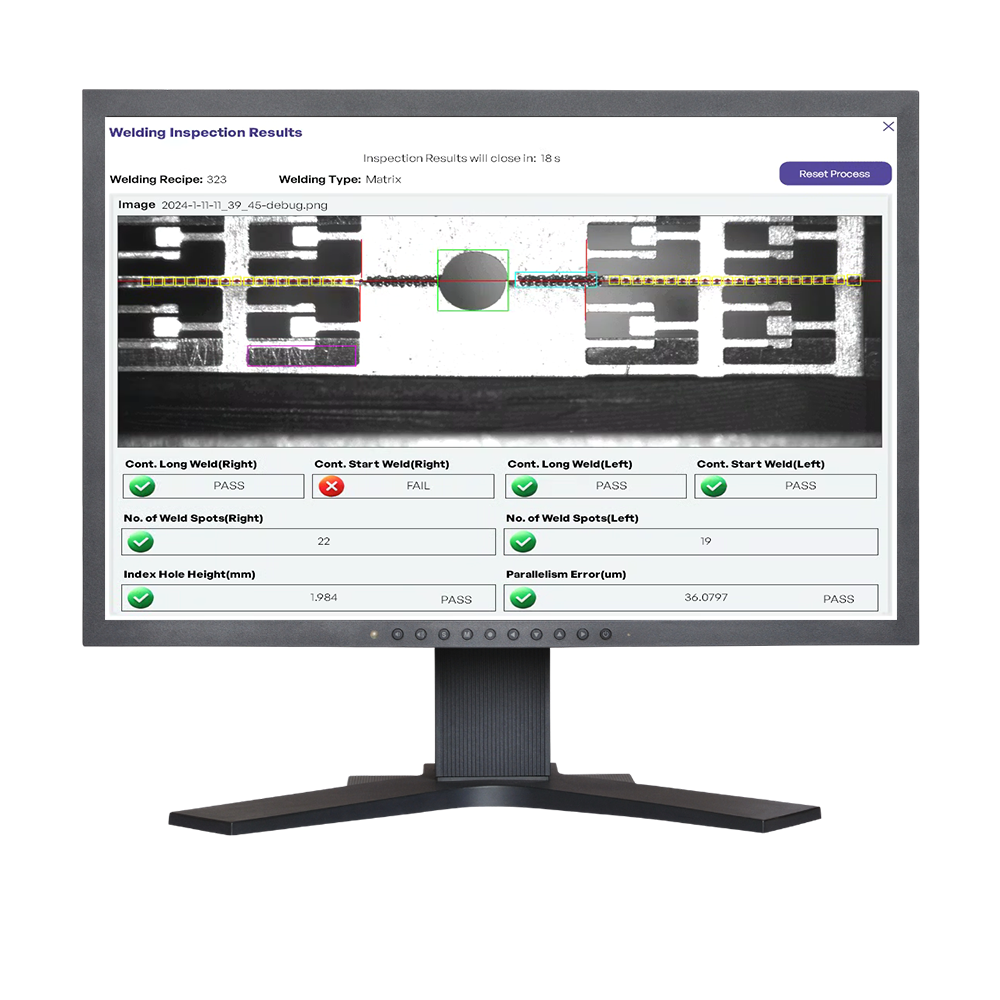

In electronics manufacturing, AI-based vision systems ensure precision and consistency at every stage of production. From defect detection and component alignment to solder joint inspection, they deliver high-speed, reliable quality control. These systems help manufacturers achieve higher yields, fewer errors, and uncompromised product quality.